Uranium and Depleted Uranium

(Updated December 2009)

http://www.world-nuclear.org/info/Nuclear-Fuel-Cycle/Uranium-Resources/Uranium-and-Depleted-Uranium/#.UhXJX3-N6So

- The basic fuel for a nuclear power reactor is uranium – a heavy metal able to release abundant concentrated energy.

- Uranium occurs naturally in the Earth's crust and is mildly radioactive.

- Depleted uranium is a by-product from uranium enrichment.

- The health hazards associated with any uranium are much the same as those for lead.

The Earth's uranium (chemical symbol U) was apparently formed in

supernovae up to about 6.6 billion years ago (see information page on The Cosmic Origins of Uranium).

Its radioactive decay provides the main source of heat inside the

Earth, causing convection and continental drift. As decay proceeds, the

final product, lead, increases in relative abundance.

Uranium was discovered by Martin Klaproth, a German chemist, in 1789

in the mineral pitchblende, and was named after the planet Uranus. It

occurs in most rocks in concentrations of 2 to 4 parts per million and

is as common in the Earth's crust as tin, tungsten and molybdenum and

about 40 times as common as silver. It is also found in the oceans, at

an average concentration of 1.3 parts per billion. There are a number of

locations in different parts of the world where it occurs in

economically-recoverable concentrations. When mined, it yields a mixed

uranium oxide product, U3O8. Uraninite, or pitchblende, is the most common uranium mineral.

In the past, uranium was also used to colour glass (from as early as

79 AD) and deposits were once mined in order to obtain its decay

product, radium. This element was used in luminous paint, particularly

on the dials of watches and aircraft instruments up to the 1950s, and in

medicine for the treatment of disease.

For many years from the 1940s, virtually all of the uranium that was

mined was used in the production of nuclear weapons, but this ceased to

be the case in the 1970s. Today the only substantial use for uranium is

as fuel in nuclear reactors, mostly for electricity generation.

Uranium-235 is the only naturally-occurring material which can sustain a

fission chain reaction, releasing large amounts of energy.

While nuclear power is the predominant use of uranium, heat from

nuclear fission can be used for industrial processes. It is also used

for marine propulsion (mostly naval). And small nuclear reactors are

important for making radioisotopes.

The uranium atom

Uranium is one of the heaviest of all the naturally-occurring

elements and has a specific gravity of 18.7. Its melting point is

1132ºC.a

Like other elements, uranium occurs in slightly differing forms known

as isotopes. These isotopes differ from each other in the number of

neutron particles in the nucleus. Natural uranium as found in the

Earth's crust is a mixture of three isotopes: uranium-238 (U-238),

accounting for 99.275%; U-235 – 0.720%; and traces of U-234 – 0.005%.

The isotope U-235 is important because under certain conditions it

can readily be split, yielding a lot of energy. It is therefore said to

be 'fissile'. Meanwhile, like all radioactive isotopes, it decays. U-238

decays very slowly, its half-lifeb

being the same as the age of the Earth. This means that it is barely

radioactive, less so than many other isotopes in rocks and sand.

Uranium-238 has a specific radioactivity of 12.4 kBq/g, and U-235 80

kBq/g, but the smaller amount of U-234 is very active (231 MBq/g) so the

specific radioactivity of natural uranium (25 kBq/g) is about double

that of U-238 despite it consisting of over 99% U-238.c In decay it generates 0.1 watts/tonne and this is enough to warm the Earth's mantle.

Uranium fission

The nucleus of the U-235 isotope comprises 92 protons and 143

neutrons (92 + 143 = 235). When the nucleus of a U-235 atom is split in

two by a neutrond,

some energy is released in the form of heat, and two or three

additional neutrons are thrown off. If enough of these expelled neutrons

split the nuclei of other U-235 atoms, releasing further neutrons, a

chain reaction can be achieved. When this happens over and over again,

many millions of times, a very large amount of heat is produced from a

relatively small amount of uranium.

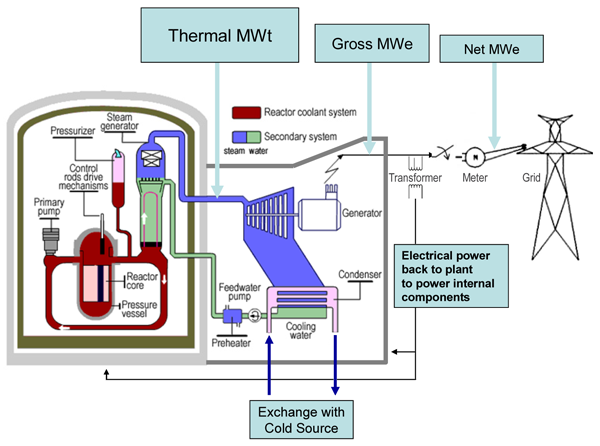

It is this process, in effect 'burning' uranium, which occurs in a

nuclear reactor. In a nuclear reactor the uranium fuel is assembled in

such a way that a controlled fission chain reaction can be achieved. The

heat created by splitting the U-235 atoms is then used to make steam

which spins a turbine to drive a generator, producing electricity.

Whereas the U-235 atom is 'fissile', the U-238 atom is said to be

'fertile'. This means that it can capture a neutron and become

(indirectly) plutonium-239, which is fissile. Pu-239 is very much like

U-235, in that it can fission following neutron capture, also yielding a

lot of energye.

Because there is so much U-238 in a reactor core (most of the fuel),

these reactions occur frequently, and in fact about one-third of the

energy yield typically comes from burning Pu-239.

Both uranium and plutonium were used to make bombs before they became

important for making electricity and radioisotopes. But the type of

uranium and plutonium for bombs is different from that in a nuclear

power plant. Bomb-grade uranium is highly enriched (>90% U-235,

instead of about 3.5-5.0% in a power plant); bomb-grade plutonium is

fairly pure (>90%) Pu-239 and is made in special reactors.

Uranium as a fuel for nuclear power

About 14% of the world's electricity is generated from uranium in nuclear reactors1. This amounts to over 2700 billion kWh, as much as from all sources worldwide in 1988.2

It comes from about 435 nuclear reactors with a total output capacity

of about 370,000 MWe operating in 30 countries. Over 50 more reactors

are under construction and another 430 are on the drawing board3.

A typical 1000 megawatt (MWe) reactor can provide enough electricity

for a modern city of close to one million people, about 7 billion kWh

per year.

Belgium, Bulgaria, Czech Republic, Finland, France, Hungary, South

Korea, Lithuania, Slovakia, Slovenia, Sweden, Switzerland and Ukraine

all get 30% or more of their electricity from nuclear reactors. Germany

and Japan derive more than a quarter of their electricity from uranium.

The USA has over 100 reactors operating, supplying 20% of its

electricity4.

Nuclear power stations and fossil-fuelled power stations of similar

capacity have many features in common. Both require heat to produce

steam to drive turbines and generators. In a nuclear power station,

however, the fissioning of uranium atoms replaces the burning of coal or

gas. The chain reaction that takes place in the core of a nuclear

reactor is controlled by rods which absorb neutrons. They are inserted

or withdrawn to set the reactor at the required power level. The fuel

elements are surrounded by a substance called a moderator to slow the

speed of the emitted neutrons and thus enable the chain reaction to

continuef. Water, graphite and heavy water are used as moderators in different types of reactors.

Sources of uranium

Uranium is widespread in many rocks, and even in seawater. However,

like other metals, it is seldom sufficiently concentrated to be

economically recoverable. Where it is, we speak of an orebody. In

defining what is ore, assumptions are made about the cost of mining and

the market price of the metal. Uranium resources are therefore

calculated as tonnes recoverable up to a certain cost.

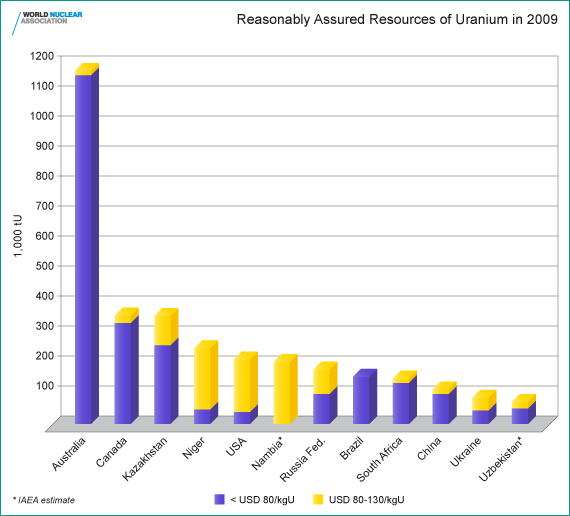

Australia's uranium resources are about 25% of the world's total, but

Canada has been the world's leading producer to 2008, then being

overtaken by Kazakhstang.

Other countries with known resources include Russian Federation, USA,

South Africa, Namibia, Niger, Brazil and Ukraine. Many more countries

have smaller deposits which could be mined. (See information page on Supply of Uranium).

Uranium is sold only to countries which are signatories of the

Nuclear Non-Proliferation Treaty, and which allow international

inspection to verify that it is used only for peaceful purposes.

From uranium ore to reactor fuel

Uranium ore can be mined by underground or open-cut methods,

depending on its depth. After mining, the ore is crushed and ground up.

Then it is treated with acid to dissolve the uranium, which is then

recovered from solution. Uranium may also be mined by in situ leaching (ISL), where it is dissolved from the orebody in situ and pumped to the surface.

The end product of the mining and milling stages, or ISL, is uranium oxide concentrate (U3O8).

Before it can be used in a reactor for electricity generation, however,

it must undergo a series of processes to produce a useable fuel.

For most of the world's reactors, the next step in making a useable

fuel is to convert the uranium oxide into a gas, uranium hexafluoride

(UF6), which enables it to be enrichedh. Enrichment increases the proportion of the U-235 isotope from its natural level of 0.7% to 3-5% (see information page on Uranium Enrichment).

This enables greater technical efficiency in reactor design and

operation, particularly in larger reactors, and allows the use of

ordinary water as a moderator. A by-product (sometimes considered a

waste product) of enrichment is depleted uranium (about 86% of the

original feed).

After enrichment, the UF6 gas is converted to uranium dioxide (UO2)

which is formed into fuel pellets. These fuel pellets are placed inside

thin metal tubes which are assembled in bundles to become the fuel

elements for the core of the reactor. UO2 has a very high melting point – 2865°C (compared with uranium metal – 1132°C).

Used reactor fuel is removed from the reactor and stored, either to be reprocessed or disposed of underground.

The uranium orebody contains both U-235 and (mostly) U-238. About 95%

of the radioactivity in the ore is from the U-238 decay series. This

has 14 radioactive isotopes in secular equilibrium, thus each represents

7% of the total. (In the case of Ranger ore - with 0.3% U308 - it has

about 450 kBq/kg, so irrespective of the mass proportion, 32 kBq/kg per

nuclide in that decay series.) When the ore is processed, the U-238 and

the very much smaller masses of U-234 (and the U-235) are removed. The

balance becomes tailings, and at this point has about 86% of its

original intrinsic radioactivity. However, with the removal of most

U-238, the following two short-lived decay products (Th-234 &

Pa-234) soon disappear, leaving the tailings with a little over 70% of

the radio-activity of the original ore after several months. The

controlling long-lived isotope then becomes Th-230 which decays with a

half life of 77,000 years to radium-226 followed by radon-222.

Recycled (reprocessed) uranium

Uranium comprises about 96% of used fuel. When used fuel is reprocessed, both plutonium and uranium are recovered separately.

Uranium recovered from reprocessing used nuclear fuel is mostly U-238

with about 1% U-235, so it needs to be converted and re-enriched. This

is complicated by the presence of impuritiesi

and two isotopes in particular, U-232 and U-236, which are formed by or

following neutron capture in the reactor, and increase with higher

burn-up levelsj.

U-232 is largely a decay product of Pu-236, and increases with storage

time in used fuel, peaking at about ten years. Both U-232 and U-236

decay much more rapidly than U-235 and U-238, and one of the daughter

products of U-232 emits very strong gamma radiation, which means that

shielding is necessary in any plant handling material with more than

very small traces of it. U-236, comprising about 0.5% of recovered

uranium, is a neutron absorber which impedes the chain reaction, and

means that a higher level of U-235 enrichment is required in the product

to compensate.

Because they are lighter than U-238, both U-232 and U-236 tend to

concentrate in the enriched (rather than depleted) output, so

reprocessed uranium (RepU) that is re-enriched for fuel must be

segregated from enriched fresh uranium. Enriched RepU has an activity of

over 250 kBq/g, which compares with 82kBq/g (most of this being from

U-234) for enriched fresh uranium. The presence of U-236 in particular

means that most reprocessed uranium can normally be recycled only once.

In the future, laser enrichment techniques may be able to remove these

difficult isotopes.

Uranium from thorium

Thorium, as well as uranium, can be used as a nuclear fuel. Although

not fissile itself, Th-232 will absorb slow neutrons to produce

uranium-233 (U-233)k,

which is fissile (and long-lived). The irradiated fuel can then be

unloaded from the reactor, the U-233 separated from the thorium, and fed

back into another reactor as part of a closed fuel cycle.

U-233 has higher neutron yield per neutron absorbed than U-235 or

Pu-239. Given a start with some other fissile material (U-233, U-235 or

Pu-239) as a driver, a breeding cycle similar to but more efficient than

that with U-238 and plutonium (in conventional thermal neutron

reactors) can be set up. The driver fuels provide all the neutrons

initially, but are progressively supplemented by U-233 as it forms from

the thorium. However, the intermediate product protactinium-233 (Pa-233)

is a neutron absorber which diminishes U-233 yield. (See information

page on Thorium).

Other uses of uranium-fuelled reactors

There are also other uses for uranium-fuelled nuclear reactors. Over

200 small nuclear reactors power some 150 ships, mostly submarines, but

ranging from icebreakers to aircraft carriers. These can stay at sea for

very long periods without having to make refuelling stops. In most such

vessels the steam drives a turbine directly geared to propulsion.

The heat produced by nuclear reactors can also be used directly

rather than for generating electricity. In Russia, for example, it is

used to heat buildings and elsewhere it provides heat for a variety of

industrial processes such as water desalination. In the future,

high-temperature reactors could be used for industrial processes such as

thermochemical production of hydrogen.

Radioisotope production in uranium fuelled reactors

Radioactive materials (radioisotopes) play a key role in the

technologies that provide us with food, water and good health and have

become a vital part of modern life. They are produced by bombarding

small amounts of particular elements with neutrons. Using relatively

small special purpose nuclear reactors (usually called research

reactors), a wide range of radioisotopes can be made at low cost. The

use of radioisotopes has become widespread since the early 1950s, and

there are now some 280 research reactors in 56 countries producing them.

In medicine, radioisotopes are widely used for diagnosis, and also

for treatment and research. Radioactive chemical tracers emit gamma

radiation which provides diagnostic information about a person's anatomy

and the functioning of specific organs. Radiotherapy also employs

radioisotopes in the treatment of some illnesses, such as cancer. More

powerful gamma sources are used to sterilise syringes, bandages and

other medical equipment. About one in two people in Western countries is

likely to experience the benefits of nuclear medicine in their

lifetime, and gamma sterilisation of equipment is almost universal. (See

information page on Radioisotopes in Medicine.)

In the preservation of food, radioisotopes are used to inhibit the

sprouting of root crops after harvesting, to kill parasites and pests,

and to control the ripening of stored fruit and vegetables. Irradiated

foodstuffs are accepted by world and national health authorities for

human consumption in an increasing number of countries. They include

potatoes, onions, dried and fresh fruits, grain and grain products,

poultry and some fish. Some prepacked foods can also be irradiated.

Agriculturally, in the growing crops and breeding livestock,

radioisotopes also play an important role. They are used to produce

high-yielding, disease- and weather-resistant varieties of crops, to

study how fertilisers and insecticides work, and to improve the

productivity and health of domestic animals. Industrially, and in

mining, they are used to examine welds, to detect leaks, to study the

rate of wear of metals, and for on-stream analysis of a wide range of

minerals and fuels. (See information page on Radioisotopes in Industry.)

Environmentally, radioisotopes are used to trace and analyse

pollutants, to study the movement of surface water, and to measure water

runoffs from rain and snow, as well as the flow rates of streams and

rivers.

Most household smoke detectors use a radioisotope (americium-241)

derived from the plutonium formed in nuclear reactors. These alarms save

many lives. (See information page on Smoke Detectors and Americium.)

Depleted uranium

Every tonne of natural uranium produced and enriched for use in a

nuclear reactor gives about 130 kg of enriched fuel (3.5% or more

U-235). The balance is depleted uranium tails (U-238, typically with

0.25-0.30% U-235). This major portion has been depleted in its fissile

U-235 isotope (and, incidentally, U-234) by the enrichment process. It

is commonly known as DU if the focus is on the actual material, or tails

if the focus is on its place in the fuel cycle and its U-235 assay.

DU tails are either stored as UF6 or (especially in France) de-converted back to U3O8,

which is more benign chemically and thus more suited for long-term

storage. It is also less chemically toxic. Every year over 50,000 tonnes

of depleted uranium joins already substantial stockpiles in the USA,

Europe and Russia. World stock is about 1.5 million tonnes.

Some DU is drawn from these stockpiles to dilute high-enriched

(>90%) uranium released from weapons programs, particularly in

Russia, and destined for use in civil reactors (see information page on Military Warheads as a Source of Nuclear Fuel).

This weapons-grade material is diluted about 25:1 with depleted

uranium, or 29:1 with depleted uranium that has been enriched slightly

(to 1.5% U-235) to minimise levels of (natural) U-234 in the product.

Some, assaying 0.25-0.40% U-235, is sent to Russia for re-enrichment,

using surplus plant capacity there to produce either natural uranium

equivalent or low-enriched uranium (4-5% U-235).

Some DU is used for mixed oxide (MOX) fuel, by mixing with plutonium (see information page on Mixed Oxide (MOX) Fuel).

Other uses depend on the metal's very high density (1.7 times that of

lead). Hence, where maximum mass must fit in minimum space, such as

aircraft control surface and helicopter counterweights, yacht keels,

etc, it is often well suited. Until the mid 1970s it was used in dental

porcelains. In addition it is used for radiation shielding, being some

five times more effective than lead in this role.

Also because of its density, it is used as solid slugs or penetrators

in armour-piercing projectiles, alloyed with abut 0.75% titanium. DU is

pyrophoric, so that upon impact about 30% of the projectile atomises

and burns to uranium oxide dust. It was widely used in the 1990/91 Gulf

War (300 tonnes) and less so in the 1998/99 Kosovo War (11 tonnes).

Health aspects of DU

Depleted uranium is not classified as a dangerous substance

radiologically, though it is a potential hazard in large quantities,

beyond what could conceivably be breathed. Its emissions are very low,

since the half-life of U-238 is the same as the age of the Earth (4.5

billion years). There are no reputable reports of cancer or other

negative health effects from radiation exposure to ingested or inhaled

natural or depleted uranium, despite much study.

However, uranium does have a chemical toxicity about the same as that

of lead, so inhaled fume or ingested oxide is considered a health

hazard. Most uranium actually absorbed into the body is excreted within

days, the balance being laid down in bone and kidneys. Its biological

effect is principally kidney damage. The World Health Organization (WHO)

has set a tolerable daily intake level for uranium of 0.6 microgram/kg

body weight, orally. (This is about eight times our normal background

intake from natural sources.) Standards for drinking water and

concentrations in air are set accordingly.

Like most radionuclides, it is not known as a carcinogen, or to cause birth defects (from effects in utero)

or to cause genetic mutations. Radiation from DU munitions depends on

how long since the uranium has been separated from the lighter isotopes

so that its decay products start to build up. Decay of U-238 gives rise

to Th-234, Pa-234 (beta emitters) and U-234 (an alpha emitter)m.

On this basis, in a few months, DU is weakly radioactive with an

activity of around 40 kBq/g quoted. (If it is fresh from the enrichment

plant and hence fairly pure, the activity is 15 kBq/g, compared with 25

kBq/g for pure natural uranium. Fresh DU from enriching reprocessed

uranium has U-236 in it and more U-234 so is about 23 kBq/g.)

In

2001, the UN Environment Programme (UNEP) examined the effects of nine

tonnes of DU munitions having been used in Kosovo, checking the sites

targeted by it5.

UNEP found no widespread contamination, no sign of contamination in

water of the food chain and no correlation with reported ill-health in

NATO peacekeepers. A two-year study6 by Sandia National Laboratories in USA reported in 2005 that consistent with earlier studiesn,

reports of serious health risks from DU exposure during the 1991 Gulf

War are not supported by medical statistics or by analysis.

An editorial in the Radiological Protection Bulletin of the UK's National Radiation Protection Board stated: "DU

is radioactive and doses from inhalation of dust or from handling bare

spent rounds need to be assessed properly. However, the scientific

consensus at present is that the risks are likely to be small and easily

avoidable, especially compared with the other risks the armed forces

have to take in war."8

Thus DU is clearly dangerous for military targets, but for anyone

else – even in a war zone – there is little hazard. Ingestion or

inhalation of uranium oxide dust resulting from the impact of DU

munitions on their targets is the main possible exposure route.

Further Information

a. See also Webelements' uranium webpage [Back]

b. The half-life is the time it takes for a radionuclide to lose half of its own radioactivity. [Back]

c. The becquerel (Bq) is a unit or measure of actual radioactivity in

material (as distinct from the radiation it emits), with reference to

the number of nuclear disintegrations per second (1 Bq = 1

disintegration/sec). For further information on units of radioactivity

see the Units of radiation and radioactivity section in the information page on Radiation and Nuclear Energy [Back]

d. U-235 can fission following capture of a low-energy (or 'thermal')

neutron to form a new compound nucleus, which then splits into two

daughter fragments and two or three neutrons (average around 2.5),

releasing energy in the process. For further information on nuclear

fission, see WNA's Some Physics of Uranium education paper [Back]

e. Sometimes Pu-239 simply captures a neutron without splitting, and

it becomes Pu-240. Because the Pu-239 is either progressively burned or

becomes Pu-240, the longer the fuel stays in the reactor the more Pu-240

accumulates in it. The significance of this is that when the used fuel

is removed after about three years, the plutonium in it is not suitable

for making weapons – because Pu-240 has a relatively high rate of

spontaneous fission – but can be recycled as fuel (see also information

page on Plutonium). [Back]

f. Neutrons released in fission are initially fast (velocity about 109 cm/sec, or energy above 1 MeV), but fission in U-235 is most readily caused by slow (thermal) neutrons (velocity about 105

cm/sec, or energy about 0.02 eV). A moderator material comprising light

atoms thus surrounds the fuel rods in a reactor to slow down the

neutrons in elastic collisions. For further information, see WNA's

education paper on Some Physics of Uranium [Back]

g. Kazakhstan is now reported to be the world's leading uranium producer – see Kazakhstan takes top spot in 2009, World Nuclear News (5 January 2010) [Back]

h. For reactors which use natural uranium as their fuel (and which require graphite or heavy water as a moderator) the U3O8 concentrate simply needs to be refined and converted directly to uranium dioxide. [Back]

i. Recovered uranium (especially from earlier military reprocessing)

may be contaminated with traces of fission products. Over 2002-06 USEC

cleaned up 7400 tonnes of technetium-contaminated uranium from the US

Department of Energy. [Back]

j. Recovered uranium also contains a higher proportion of U-234 than

fresh reactor fuel. As well as having a greater specific activity than

both U-235 and U-238, the presence of U-234 alters the reactivity as it

absorbs neutrons. [Back]

k.

Neutron absorption by Th-232 produces Th-233, which has a half-life of

about 22 minutes. This undergoes beta decay to form Pa-233 (half-life 27

days), most of which forms U-233 by further beta decay. Around 11% of

the U-233 is converted by further neutron absorption to U-235, which is

the fissile isotope of uranium used in conventional nuclear reactors. A

small amount of the Pa-233 and U-233 forms U-232 in the reactor.

Separated U-233 is therefore always contaminated with traces of U-232,

which has a 69-year half-life but whose daughter productsl,

particularly thallium-208, are strong gamma emitters with very short

half-lives. This creates significant problems in handling the bred U-233

and makes it easy to detect, hence conferring proliferation resistance.

[Back]

l. The decay chain of U-232 has six short-lived decay products before Tl-208, which precedes stable Pb-208. [Back]

m. U-238 (half-life 4.5 billion years) decays to thorium-234

(half-life 24 days), which beta decays to protactinium-234 (half-life

one minute), which beta decays to U-234 (alpha emitter, half-life

246,000 years). [Back]

n. For example, a 2001 paper by the Australasian Radiation Protection Society (ARPS)7,

which quotes several studies, concludes that health risks associated

with the levels of DU exposure experienced during the Gulf War are

essentially zero. A summary of the ARPS statement reads as follows:

Some military personnel involved in the 1991 Gulf War complained

of continuing stress-like symptoms for which no obvious cause was found.

These symptoms were at times attributed to the use of depleted uranium

in shells and other missiles, which are said to have caused toxic

effects. Similar complaints arose from later fighting in the Balkans

(Kosovo). Because of the latency period for the induction of cancer by

radiation, it is not credible that any cases of radiation-induced cancer

could in the short term be attributed to the Kosovo conflict.

Furthermore, extensive studies have concluded that no radiological

health hazard should be expected from exposure to depleted uranium. The

risk from external exposure is essentially zero, even when pure metal is

handled. No detectable increases of cancer, leukaemia, birth defects or

other negative health effects have ever been observed from radiation

exposure to inhaled or ingested natural uranium concentrates, at levels

far exceeding those likely in areas where DU munitions have been used.

This is mainly because the low radioactivity per unit mass of uranium

means that the mass needed for significant internal exposure would be

virtually impossible to accumulate in the body – and DU is less than

half as radioactive as natural uranium. [Back]

1. Key World Energy Statistics 2009, OECD International Energy Agency, 9 rue de la Fédération, 75739 Paris Cedex 15, France (2009) [Back]

2. Table 8.2a of Annual Energy Review 2008, U.S. Energy Information Administration, Report No. DOE/EIA-0384(2008) [Back]

3. World Nuclear Association table of World Nuclear Power Reactors & Uranium Requirements [Back]

4. World Nuclear Association table of Nuclear share figures [Back]

5. Depleted Uranium in Kosovo: Post-Conflict Environmental Assessment United Nations Environment Programme (2001) [Back]

6. Albert C. Marshall, An Analysis of Uranium Dispersal and Health Effects Using a Gulf War Case Study, Sandia National Laboratories, USA, SAND2005-4331 (July 2005) [Back]

7. Potential Health Effects of Depleted Uranium in Munitions, Australasian Radiation Protection Society media release (8 February 2001) [Back]

8. Michael Clark, Editorial, Radiological Protection Bulletin No. 229, P3 (March 2001), National Radiological Protection Board [Back]

General sources

World Health Organization fact sheet on depleted uranium

US Department of Energy Depleted UF6 Management Information Network website (http://web.ead.anl.gov/uranium/)

Radiation Protection Bulletin No. 167, P.13-16 (July 1995), National Radiological Protection Board

Balkans Task Force Final Report, The Kosovo Conflict – Consequences for the Environment & Human Settlements, United Nations Environment Programme and United Nations Centre for Human Settlements (Habitat), ISBN 9280718011 (1999)

Management of Depleted Uranium, OECD Nuclear Energy Agency, OECD Publishing, ISBN 9789264195257 (Aug 2001)

Bulletin of the Atomic Scientists, Volume 55, Number 6, (November-December 1999)

The Cosmic Origins of Uranium

(November 2006)

- Uranium drives 16% of our electricity worldwide, yet this fact pales into insignificance when we consider the role uranium has played in the evolution of the Earth.

- The Earth's uranium was produced in one or more supernovae over 6 billion years ago.

- Uranium later became enriched in the continental crust.

Geologists and geochemists have been studying the abundance,

distribution and chronometric potential of the isotopes of uranium for

more than a century. Their work stems from Klaproth's discovery in 1789

of the heaviest naturally occurring element, Becquerel's demonstration

in 1896 that uranium salts are radioactive, Boltwood's conclusion in

1905 that lead as well as helium is a decay product of uranium, and

Rutherford's suggestion in 1906 of the geological time-keeping potential

of radioactivity. From a geochemical point of view, some of the major

questions are:

- Where did the uranium now in the Earth come from?

- What effects has the comparatively trivial uranium content of the Earth had on the evolution of the planet and, conversely, are there feedbacks controlling the geochemical cycle of uranium that vary secularly (i.e. over long, indefinite periods of time)?

- Can we track through time the way uranium has been recycled through the exosphere, crust and mantle of the Earth?

Cosmic abundance of elements

For many years, since the 1930s, a large number of scientists have

been occupied with determining the abundances of the elements and their

isotopes in the objects comprising the solar system, and with accounting

for the abundance patterns observed. In fact, spectroscopic

measurements show that the abundances of elements in stars vary and that

there is no single applicable 'cosmic abundance' pattern.

Closer to home, there are major differences in abundances of the

elements in the various planets that orbit our hydrogen-helium dominated

Sun. The terrestrial planets, including the Earth, are relatively

depleted in the potentially gaseous or volatile elements (hydrogen,

helium, carbon and neon) and are dominated by elements of low and even

atomic number (oxygen, magnesium, silicon and iron). On this scale,

uranium - the abundance of which in the Sun is only 10 -12

that of hydrogen - is an exceedingly rare element. Furthermore,

measurements of oxygen isotopes in meteorites show that the solar system

as a whole is not homogeneous in terms of isotopic ratios. All these

variations point to a conclusion that multiple sources were involved in

the production of proto-solar system material.

Where did uranium come from?

Cosmochemists have been concerned not only with patterns and secular

trends of abundance of the elements in galaxies but also with the

origins of abundance anomalies in particular stars and with theories on

the synthesis of different nuclei to account for these observations.

According to the theories developed, the Earth's uranium was produced in

one or more supernovae ("An explosive brightening of a star in which

the energy radiated by it increases by a factor of ten billion ... A

supernova explosion occurs when a star has burned up all its available

nuclear fuel and the core collapses catastrophically." - Oxford

Dictionary of Physics). The main process concerned was the rapid capture

of neutrons on seed nuclei at rates greater than disintegration through

radioactivity. The neutron fluxes required are believed to occur during

the catastrophically explosive stellar events called supernovae.

Gravitational compression of iron (the island of nuclear stability,

incapable of further exothermic fusion reactions) and sudden collapse in

the centre of a massive star triggers the explosive ejection of much of

the star into space, together with a flood of neutrons. Remnants of

hundreds of supernovae have been found, and we "witnessed" one in the

Magellanic Clouds in 1987.

So, we know that the Earth's uranium was produced through this

process in one or more supernovae, and that this material was inherited

by the solar system of which the Earth is a part.

We might further ask how long ago this synthesis of uranium occurred. Given

- the present day abundances of U-235 and U-238 in the various 'shells' forming our planet,

- a knowledge of the half-lives of these isotopes, and

- the age of the Earth (c 4.55 billion years) - known from various radiometric 'clocks', including those of the uranium-to-lead decay chains.

We can calculate the abundances of U-235 and U-238 at the time the

Earth was formed. Knowing further that the production ratio of U-235 to

U-238 in a supernova is about 1.65, we can calculate that if all of the

uranium now in the solar system were made in a single supernova, this

event must have occurred some 6.5 billion years ago.

This 'single stage' is, however, an oversimplification. In fact,

multiple supernovae from over 6 billion to about 200 million years ago

were involved. Additionally, studies of the isotopic abundances of

elements, such as silicon and carbon in meteorites, have shown that more

than ten separate stellar sources were involved in the genesis of solar

system material. Thus the relative abundance of U-235 and U-238 at the

time of formation of the solar system:

- cannot be inverted to a 'single stage' model age,

- is essentially an accidental and unique value, and

- reflects the input of the explosive debris of many progenitor stars.

Enrichment in Earth's crust

Many analyses have been made of the uranium in the rocks forming the

continental and oceanic crusts, and in samples of the Earth's mantle

exposed as uplifted slices in mountain belts or as 'xenoliths' in

basalts and kimberlites (hosts of diamonds).

We can have some confidence that these measurements are robust for

the crust and upper mantle of the Earth, but less confidence that we

know the abundance of uranium in the lower mantle and the outer and

inner cores. While on average the abundance of uranium in meteorites is

about 0.008 parts per million (gram/tonne), the abundance of uranium in

the Earth's 'primitive mantle' - prior to the extraction of the

continental crust - is 0.021 ppm. Allowing for the extraction of a

core-forming iron-nickel alloy with no uranium (because of the

characteristic of uranium which makes it combine more readily with

minerals in crustal rocks rather than iron-rich ones), this still

represents a roughly twofold enrichment in the materials forming the

proto-Earth compared with average meteoritic materials.

The present-day abundance of uranium in the 'depleted' mantle exposed

on the ocean floor is about 0.004 ppm. The continental crust, on the

other hand, is relatively enriched in uranium at some 1.4 ppm. This

represents a 70-fold enrichment compared with the primitive mantle. In

fact, the uranium lost from the 'depleted' oceanic mantle is mostly

sequestered in the continental crust.

It is likely that the process or processes which transferred uranium

from the mantle to the continental crust are complex and multi-step.

However, for at least the past 2 billion years they have involved:

- formation of oceanic crust and lithosphere through melting of the mantle at mid-ocean ridges,

- migration of this oceanic lithosphere laterally to a site of plate consumption (this is marked at the surface by a deep-sea trench),

- production of fluids and magmas from the downgoing (subducted) lithospheric plate and overriding mantle 'wedge' in these subduction zones,

- transfer of these fluids/melts to the surface in zones of 'island arcs' (such as the Pacific's Ring of Fire),

- production of continental crust from these island arc protoliths, through remelting, granite formation and intra-crustal recycling.

All through this crust-forming cycle, the lithophile character of

uranium is manifest in the constancy of the potassium to uranium ratio

at about 10,000 in the rock range from peridotite to granite. Because we

would like to keep track of how uranium is distributed in the Earth,

the abundance and isotopic characteristics of lead - the radiogenic

daughter of U-235 and U-238 - are useful parameters. Table 1

below highlights the relatively low abundance of lead in the Earth's

mantle and the consequent high uranium to lead ratio, compared with

meteorites. The difference in abundance can most likely be explained by

lead's volatile nature and tendency to combine with iron, with lead

being lost during terrestrial accretion and core separation. One of the

consequences, of course, of these high ratios is the comparatively high

radiogenic/non-radiogenic content of Pb-207/Pb-204 and Pb-206/Pb-204 in

the Earth's crust and mantle compared with meteorites or the earth's

core. (Pb-207 is the final stable decay product of U-235, and Pb-206 is

that of U-238. Pb-204 is non-radiogenic.

Table 1

| U abundance (ppm) |

Pb abundance (ppm) |

U/Pb ratio | |

| Meteorites | 0.008 | 2.470 | 0.003 |

|---|---|---|---|

| Primitive mantle | 0.021 | 0.185 | 0.113 |

| Continental crust | 1.4 | 12.6 | 0.111 |

The figure given for the continental crust is an average of the

entire crust. Of course, local concentration of uranium can far exceed

these values, ranging up to 50 ppm disseminated in some granites, to

much higher values in ore deposits. In fact, in the geological past,

local concentrations of uranium have occasionally achieved natural

criticality, for example the Oklo reactors in Gabon.

Energy source

Convection in the outer core and the mantle, whereby heat is

transferred by movement of heated matter, governs many of the Earth's

endogenous processes.

The convection in the core may be driven by the heat released during

progressive solidification of the core (latent heat of crystallisation)

and leads to the self-sustaining terrestrial dynamo which is the source

of the Earth's magnetic field. Heat transfer from the core at the

core/mantle boundary is also believed to trigger upwellings of

relatively hot, and hence low density, plumes of material. These plumes

then ascend, essentially without gaining or losing heat, and undergo

decompression melting close to the Earth's surface at 'hot spots' like

Hawaii, Reunion and Samoa.

However, the primary source of energy driving the convection in the

mantle is the radioactive decay of uranium, thorium and potassium. In

the present Earth, most of the energy generated is from the decay of

U-238 (c 10-4 watt/kg). At the time of the Earth's formation,

however, decay of both U-235 and K-40 would have been subequal in

importance and both would have exceeded the heat production of U-238.

A simple way of viewing the process of plate tectonics - the

formation and disposal of oceanic lithosphere - is that this is the

mechanism by which the mantle sheds heat. Conversely, 'mantle plumes/hot

spots' are the way the core sheds heat. In terms of total heat loss

from the Earth at present, plate activity constitutes about 74%, hot

spots account for approximately 9% and radiogenic heat lost directly

from the continental crust is some 17%. The Earth is well insulated

thermally and the heat loss from the surface now can reflect heat

generation a considerable time in the past.

Measurements of heat have led to estimates that the Earth is

generating between 30 and 44 terawatts of heat, much of it from

radioactive decay. Measurements of antineutrinos have provisionally

suggested that about 24 TW arises from radioactive decay. Professor Bob

White provides the more recent figure of 17 TW from radioactive decay in

the mantle. This compares with 42-44 TW heat loss at the Earth's

surface from the deep Earth. The balance comes from changes in the core.

(There is very much greater heat loss arising from incident solar

radiation, which is quite distinct.)

Atmosphere and greenhouse effect, the role of plants

Apart from the fundamental physical and chemical differentiation of

the Earth driven by plate tectonics, lithosphere formation and

destruction are also critical for many processes in the outer layer of

the atmosphere. We know, for example, that during periods of enhanced

oceanic lithosphere formation, such as occurred during the Cretaceous

period some 100 million years ago, the mid-ocean ridges stood higher,

triggering flooding of the low-lying portions of the continents. In fact

the Laurasian part of the former Pangea supercontinent was drowned to a

greater extent than the Gondwana part, maybe reflecting some

deep-seated thermal/compositional contrast. The effects were manifold

and include:

- enhanced carbon dioxide release causing increased carbon dioxide content of the ocean and the atmosphere,

- diminished continental surface area leading to a reduction in the titration through weathering of atmospheric carbon dioxide,

- sustained high atmospheric carbon dioxide levels leading to an enhanced greenhouse effect and warmer climate.

Secular changes have taken place in several atmospheric processes,

including a change in composition, from relatively reducing to

astonishingly oxidising. The odd-looking "equation" for atmosphere

production is:

CO2 + H2 = N2 + O2

where the primary, volcanically degassed inputs to the atmosphere are

on the left, and the cumulative abundant components are on the right

hand side of the equation. Nitrogen is a trace volcanic emission, not

utilised to any great extent in surface processes - including the

trivial effect of organic life - and merely accumulates in the

atmosphere. The Earth's distance from the Sun, together with the

greenhouse feedback, allows surface temperatures to be generally

sustained within the condensation range for water. Carbon dioxide

dissolves in water and is also sequestered in calcite by inorganic and

organic precipitation as limestone.

The remarkable feature of our atmosphere is the presence of molecular

oxygen released through photosynthesis, the process by which green

plants manufacture their carbohydrates from atmospheric carbon dioxide

and water:

6CO2 + 6H2O = C6H12O6 + 6O2

Photosynthesis can be traced back in time to about 3.8 billion years.

For a while, the oxygen released was consumed through oxidation of

reduced ferrous compounds at the Earth's surface. Ultimately, the oxygen

started to accumulate in the atmosphere as free oxygen some 2.5 billion

years ago.

In addition to many other effects, the change in the redox character

of the exosphere led to a fundamental change in the way uranium was

transported in the weathering-erosion-deposition cycle. Whereas under

reduced conditions uranium is relatively insoluble and stable as

uraninite (UO2), under oxidising conditions it becomes soluble (U6+)

and readily transported. Since 2.5 billion years ago ore deposits of

uranium have been formed primarily where reduction of uranium-bearing

fluids was achieved, for example by bacteria or through contact with

graphitic shales.

Uranium distribution through time

The oxidising atmosphere also led to an increased concentration of

uranium in the oceans and thence via transport in recirculating

hydrothermal fluids to relative enrichment in the oceanic crust. The

enhanced uranium transport from the exosphere to the Earth's interior -

via subduction of oceanic lithosphere and the subsequent

rehomogenisation of this lithosphere into the Earth's mantle - has had a

significant effect on the present distribution of uranium in the Earth,

and may account for some curious inconsistencies in the isotopic

characteristics of the mantle. For example, whereas the time-integrated

Pb-208 (stable final decay product of Th-232)/Pb-206 values of mid-ocean

ridge basalts indicate mantle source values of Th/U of about 4, the

measured values of Th/U and systematics of short-lived Th-U

disequilibria indicate a ratio of about 2. It is likely that since about

2.5 billion years ago injections of uranium into the mantle have been

effective in the reduction of the thorium to uranium ratio on an (upper)

mantle-wide scale.

An additional net effect is the selective reinjection of uranium as

opposed to lead - which is mostly stripped out in subduction zones and

returned immediately to the crust - into the mantle. We know that

overall, most basalts are being produced from a mantle with an enhanced

uranium/lead ratio and with apparent 'future' ages, compared with the

lead isotopic ratios characteristic of a closed system, single stage

evolution of uranium/lead in the Earth. This feature is sometimes

referred to by geochemists as the 'lead paradox', and may in part relate

to the feedback influence of an oxidising, life-triggered exosphere on

the interior of the Earth.

Natural nuclear reactors in the Earth's crust

At Oklo in Gabon, West Africa, about 2 billion years ago, at least 17

natural nuclear reactors commenced operation in a rich deposit of

uranium ore. Each operated at about 20 kW thermal. At that time the

concentration of U-235 in all natural uranium was 3.7 percent instead of

0.7 percent as at present (U-235 decays much faster than U-238, whose

half-life is about the same as the age of this planet.).

These natural chain reactions, started spontaneously by the presence

of water acting as a moderator, continued for about two million years

before finally dying away. During this long reaction period about 5.4

tonnes of fission products as well as 1.5 tonnes of plutonium together

with other transuranic elements were generated in the orebody. The

initial radioactive products have long since decayed into stable

elements but study of the amount and location of these has shown that

there was little movement of radioactive wastes during and after the

nuclear reactions. Plutonium and the other transuranics remained

immobile.

Georeactor theory

A quite different view of the role of uranium in the Earth is the

theory that much of the uranium in the primordial planet sunk to the

core and has formed a core there, some 8 km across, which has been

fissioning ever since. The depletion of U-235 over geological time has

not terminated the reaction because this core is a fast reactor (not

requiring any moderator) which breeds plutonium-239 from the U-238. The

georeactor theory has relatively little supporting evidence, and is not

widely supported.

Sources:

This paper, apart from the last two sections, and an addition quantifying internal energy generation, is by Prof. Richard Arculus, Australian National University, and is used with the author's permission. It is based on a paper presented by Professor Arculus at the Uranium Institute Mid-Term Meeting in Adelaide on 17 April 1996.

New Scientist 7/8/04.

This paper, apart from the last two sections, and an addition quantifying internal energy generation, is by Prof. Richard Arculus, Australian National University, and is used with the author's permission. It is based on a paper presented by Professor Arculus at the Uranium Institute Mid-Term Meeting in Adelaide on 17 April 1996.

New Scientist 7/8/04.

Supply of Uranium

(updated August 2012)http://www.world-nuclear.org/info/Nuclear-Fuel-Cycle/Uranium-Resources/Supply-of-Uranium/#.UhXLY3-N6So

- Uranium is a relatively common metal, found in rocks and seawater. Economic concentrations of it are not uncommon.

- Its availability to supply world energy needs is great both geologically and because of the technology for its use.

- Quantities of mineral resources are greater than commonly perceived.

- The world's known uranium resources increased 15% in two years to 2007 due to increased mineral exploration.

Uranium is a relatively common element in the crust of the Earth

(very much more than in the mantle). It is a metal approximately as

common as tin or zinc, and it is a constituent of most rocks and even of

the sea. Some typical concentrations are: (ppm = parts per million).

| Very high-grade ore (Canada) - 20% U | 200,000 ppm U |

|---|---|

| High-grade ore - 2% U, | 20,000 ppm U |

| Low-grade ore - 0.1% U, | 1,000 ppm U |

| Very low-grade ore* (Namibia) - 0.01% U | 100 ppm U |

| Granite | 3-5 ppm U |

| Sedimentary rock | 2-3 ppm U |

| Earth's continental crust (av) | 2.8 ppm U |

| Seawater | 0.003 ppm U |

* Where uranium is at low levels in rock or sands

(certainly less than 1000 ppm) it needs to be in a form which is easily

separated for those concentrations to be called "ore" - that is,

implying that the uranium can be recovered economically. This means

that it need to be in a mineral form that can easily be dissolved by

sulfuric acid or sodium carbonate leaching.

An orebody is, by definition, an occurrence of mineralisation from

which the metal is economically recoverable. It is therefore relative to

both costs of extraction and market prices. At present neither the

oceans nor any granites are orebodies, but conceivably either could

become so if prices were to rise sufficiently.

Measured resources of uranium, the amount known to be economically

recoverable from orebodies, are thus also relative to costs and prices.

They are also dependent on the intensity of past exploration effort, and

are basically a statement about what is known rather than what is there

in the Earth's crust - epistemology rather than geology. See Appendix 2

for mineral resource and reserve categories.

Changes in costs or prices, or further exploration, may alter

measured resource figures markedly. At ten times the current price,

seawater might become a potential source of vast amounts of uranium.

Thus, any predictions of the future availability of any mineral,

including uranium, which are based on current cost and price data and

current geological knowledge are likely to be extremely conservative.

From time to time concerns are raised that the known resources might

be insufficient when judged as a multiple of present rate of use. But

this is the Limits to Growth fallacy, a major intellectual blunder

recycled from the 1970s, which takes no account of the very limited

nature of the knowledge we have at any time of what is actually in the

Earth's crust. Our knowledge of geology is such that we can be confident

that identified resources of metal minerals are a small fraction of

what is there. Factors affecting the supply of resources are discussed

further and illustrated in the Appendix.

Uranium availability

With those major qualifications the following Table gives some idea

of our present knowledge of uranium resources. The total and several

country figures are lower than two years earlier due to economic

factors, notably inflation of production costs. It can be seen that

Australia has a substantial part (about 31 percent) of the world's

uranium, Kazakhstan 12 percent, and Canada and Russia 9 percent each.

Known Recoverable Resources of Uranium 2011

| tonnes U | percentage of world | |

| Australia |

1,661,000

|

31%

|

|---|---|---|

| Kazakhstan |

629,000

|

12%

|

| Russia |

487,200

|

9%

|

| Canada |

468,700

|

9%

|

| Niger |

421,000

|

8%

|

| South Africa |

279,100

|

5%

|

| Brazil |

276,700

|

5%

|

| Namibia |

261,000

|

5%

|

| USA |

207,400

|

4%

|

| China |

166,100

|

3%

|

| Ukraine |

119,600

|

2%

|

| Uzbekistan |

96,200

|

2%

|

| Mongolia |

55,700

|

1%

|

| Jordan |

33,800

|

1%

|

| other |

164,000

|

3%

|

| World total |

5,327,200

|

Reasonably Assured Resources plus Inferred Resources, to US$ 130/kg U, 1/1/11, from OECD NEA & IAEA, Uranium 2011: Resources, Production and Demand ("Red Book"). The total to US$ 260/kg U is 7,096,600 tonnes U, and Namibia moves up ahead of Niger.

Current usage is about 68,000 tU/yr. Thus the world's present

measured resources of uranium (5.3 Mt) in the cost category around

present spot prices and used only in conventional reactors, are enough

to last for about 80 years. This represents a higher level of assured

resources than is normal for most minerals. Further exploration and

higher prices will certainly, on the basis of present geological

knowledge, yield further resources as present ones are used up.

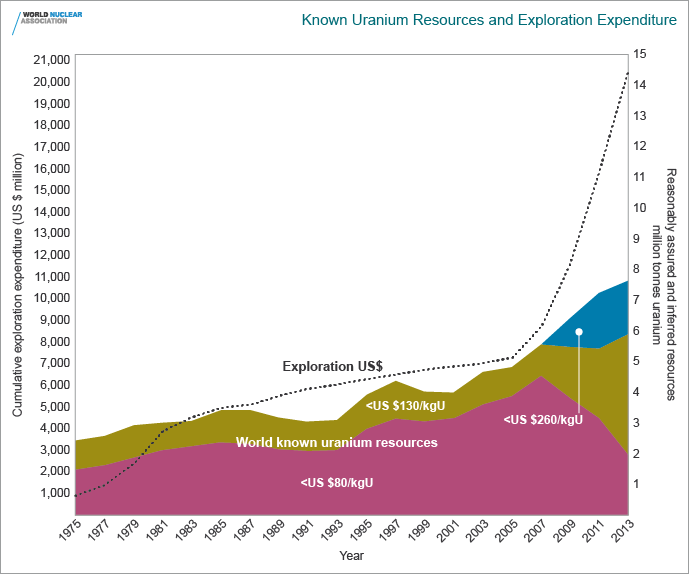

An initial uranium exploration cycle was military-driven, over 1945

to 1958. The second cycle was about 1974 to 1983, driven by civil

nuclear power and in the context of a perception that uranium might be

scarce. There was relatively little uranium exploration between 1985 and

2003, so the significant increase in exploration effort since then

could conceivably double the known economic resources despite

adjustments due to increasing costs. In the two years 2005-06 the

world’s known uranium resources tabulated above and graphed below

increased by 15% (17% in the cost category to $80/kgU). World uranium

exploration expenditure is increasing, as the the accompanying graph

makes clear. In the third uranium exploration cycle from 2003 to the end

of 2011 about US$ 10 billion was spent on uranium exploration and

deposit delineation on over 600 projects. In this period over 400 new

junior companies were formed or changed their orientation to raise over

US$ 2 billion for uranium exploration. About 60% of this was spent on

previously-known deposits. All this was in response to increased uranium

price in the market and the prospect of firm future prices.

The price of a mineral commodity also directly determines the amount

of known resources which are economically extractable. On the basis of

analogies with other metal minerals, a doubling of price from present

levels could be expected to create about a tenfold increase in measured

economic resources, over time, due both to increased exploration and the

reclassification of resources regarding what is economically

recoverable.

This is in fact suggested in the IAEA-NEA figures if those covering

estimates of all conventional resources (U as main product or major

by-product) are considered - another 7.6 million tonnes (beyond the 5.3

Mt known economic resources), which takes us to 190 years' supply at

today's rate of consumption. This still ignores the technological factor

mentioned below. It also omits unconventional resources (U recoverable

as minor by-product) such as phosphate/ phosphorite deposits (up to 22

Mt U), black shales (schists) and lignite (0.7 Mt U), and even seawater

(up to 4000 Mt), which would be uneconomic to extract in the foreseeable

future, although Japanese trials using a polymer braid have suggested

costs a bit over $250/kgU.

Research proceeds.

It is clear from this Figure that known uranium resources have

increased almost threefold since 1975, in line with expenditure on

uranium exploration. (The decrease in the decade 1983-93 is due to some

countries tightening their criteria for reporting. If this were carried

back two decades, the lines would fit even more closely. The change

from 2007 to 2009 is due to reclassifying resources into higher-cost

categories.) Increased exploration expenditure in the future is likely

to result in a corresponding increase in known resources, even as

inflation increases costs of recovery and hence tends to decrease the

figures in each cost category.

About 20% of US uranium came from central Florida's phosphate

deposits to the mid 1990s, as a by-product, but it then became

uneconomic. With higher uranium prices today the resource is being

examined again, as is another lower-grade one in Morocco. Plans for

Florida extend only to 400 tU/yr at this stage. See also companion paper

on Uranium from Phosphate Deposits.

Coal ash is another easily-accessible though minor uranium resource

in many parts of the world. In central Yunnan province in China the

coal uranium content varies up to 315 ppm and averages about 65 ppm.

The ash averages about 210 ppm U (0.021%U) - above the cut-off level for

some uranium mines. The Xiaolongtang power station ash heap contains

over 1000 tU, with annual arisings of 190 tU. Recovery of this by acid

leaching is about 70% in trials. This project has yet to announce any

commercial production, however.

Widespread use of the fast breeder reactor could increase the

utilisation of uranium 50-fold or more. This type of reactor can be

started up on plutonium derived from conventional reactors and operated

in closed circuit with its reprocessing plant. Such a reactor, supplied

with natural or depleted uranium for its "fertile blanket", can be

operated so that each tonne of ore yields 60 times more energy than in a

conventional reactor.

see also WNA position paper.

Reactor Fuel Requirements

The world’s power reactors, with combined capacity of some 375 GWe,

require about 68,000 tonnes of uranium from mines or elsewhere each

year. While this capacity is being run more productively, with higher

capacity factors and reactor power levels, the uranium fuel requirement

is increasing, but not necessarily at the same rate. The factors

increasing fuel demand are offset by a trend for higher burn-up of fuel

and other efficiencies, so demand is steady. (Over the years 1980 to

2008 the electricity generated by nuclear power increased 3.6-fold while

uranium used increased by a factor of only 2.5.)

Reducing the tails assay in enrichment reduces the amount of natural

uranium required for a given amount of fuel. Reprocessing of used fuel

from conventional light water reactors also utilises present resources

more efficiently, by a factor of about 1.3 overall.

Today's reactor fuel requirements are met from primary supply (direct

mine output - 78% in 2009) and secondary sources: commercial

stockpiles, nuclear weapons stockpiles, recycled plutonium and uranium

from reprocessing used fuel, and some from re-enrichment of depleted

uranium tails (left over from original enrichment). These various

secondary sources make uranium unique among energy minerals.

Nuclear Weapons as a source of fuel

An important source of nuclear fuel is the world's nuclear weapons

stockpiles. Since 1987 the United States and countries of the former

USSR have signed a series of disarmament treaties to reduce the nuclear

arsenals of the signatory countries by approximately 80 percent.

The weapons contained a great deal of uranium enriched to over 90

percent U-235 (ie up to 25 times the proportion in reactor fuel). Some

weapons have plutonium-239, which can be used in mixed-oxide (MOX) fuel

for civil reactors. From 2000 the dilution of 30 tonnes of military

high-enriched uranium has been displacing about 10,600 tonnes of uranium

oxide per year from mines, which represents about 15% of the world's

reactor requirements.

Details of the utilisation of military stockpiles are in the paper Military warheads as a source of nuclear fuel.

Other secondary sources of uranium

The most obvious source is civil stockpiles held by

utilities and governments. The amount held here is difficult to

quantify, due to commercial confidentiality. As at January 2009 some

129,000 tU total inventory was estimated for utilities, 10,000 tU for

producers and 15,000 tU for fuel cycle participants, making a total of

154,000 tU (WNA Market Report). These reserves are expected not to be

drawn down, but to increase steadily to provide energy security for

utilities and governments.

Recycled uranium and plutonium is another source,

and currently saves 1500-2000 tU per year of primary supply, depending

on whether just the plutonium or also the uranium is considered. In

fact, plutonium is quickly recycled as MOX fuel, whereas the reprocessed

uranium (RepU) is mostly stockpiled. See also Processing of Used Nuclear Fuel for Recycle paper.

Re-enrichment of depleted uranium (DU, enrichment

tails) is another secondary source. There is about 1.5 million tonnes

of depleted uranium available, from both military and civil enrichment

activity since the 1940s, most at tails assay of 0.25 - 0.35% U-235.

Non-nuclear uses of DU are very minor relative to annual arisings of

over 35,000 tU per year. This leaves most DU available for mixing with

recycled plutonium on MOX fuel or as a future fuel resource for fast

neutron reactors. However, some that has relatively high assay can be

fed through under-utilised enrichment plants to produce natural uranium

equivalent, or even enriched uranium ready for fuel fabrication.

Russian enrichment plants have treated 10-15,000 tonnes per year of DU

assaying over 0.3% U-235, stripping it down to 0.1% and producing a few

thousand tonnes per year of natural uranium equivalent. This Russian

program treating Western tails has now finished, but a new US one is

expected to start when surplus capacity is available, treating about

140,000 tonnes of old DU assaying 0.4% U-235.

International fuel reserves

There have been three major initiatives to set up international

reserves of enriched fuel, two of them multilateral ones, with fuel to

be available under International Atomic Energy Agency (IAEA) auspices

despite any political interruptions which might affect countries needing

them. The third is under US auspices, and also to meet needs arising

from supply disruptions.

In November 2009 the IAEA Board approved a Russian proposal to create an international "fuel bank" or guaranteed reserve of low-enriched uranium under IAEA control at the International Uranium Enrichment Centre (IUEC) at Angarsk. This Russian LEU reserve was established a year later and comprises 120 tonnes of low-enriched uranium as UF6, enriched 2.0 - 4.95% U-235 (with 40t of latter), available to any IAEA member state in good standing which is unable to procure fuel for political reasons. It is fully funded by Russia, held under safeguards, and the fuel will be made available to IAEA at market rates, using a formula based on spot prices. Following an IAEA decision to allocate some of it, Rosatom will transport material to St Petersburg and transfer title to IAEA, which will then transfer ownership to the recipient.

This initiative complements the proposed IAEA fuel bank by making more material available to the IAEA for assurance of fuel supply to countries without their own fuel cycle facilities. The 120 tonnes uranium as UF6 is equivalent to two full fuel loads for a typical 1000 MWe reactor, and is (in 2011) worth some US$ 250 million.

In December 2010 the IAEA board resolved to establish a similar guaranteed reserve of low-enriched uranium, the IAEA LEU bank, with the support of $50 million from the US-based Nuclear Threat Initiative (NTI) organization and US billionaire Warren Buffett, plus a matching $107 million from the US government ($50 million), the EU ($32 million), UAE ($10 million), Kuwait ($10 million) and Norway ($5 million). The IAEA is drawing up a framework that defines the "fuel bank's" structure, access and location. It will comprise a physical stock of UF6 at enrichment levels ranging up to 4.95% U-235 and owned by the IAEA, which shall "be responsible for storing and protecting" it. A comprehensive Host State Agreement will need to provide for the IAEA facility to be extraterritorial. Kazakhstan has offered to host it, and the IAEA has examined two proffered sites. See IAEA Factsheet.

In November 2009 the IAEA Board approved a Russian proposal to create an international "fuel bank" or guaranteed reserve of low-enriched uranium under IAEA control at the International Uranium Enrichment Centre (IUEC) at Angarsk. This Russian LEU reserve was established a year later and comprises 120 tonnes of low-enriched uranium as UF6, enriched 2.0 - 4.95% U-235 (with 40t of latter), available to any IAEA member state in good standing which is unable to procure fuel for political reasons. It is fully funded by Russia, held under safeguards, and the fuel will be made available to IAEA at market rates, using a formula based on spot prices. Following an IAEA decision to allocate some of it, Rosatom will transport material to St Petersburg and transfer title to IAEA, which will then transfer ownership to the recipient.

This initiative complements the proposed IAEA fuel bank by making more material available to the IAEA for assurance of fuel supply to countries without their own fuel cycle facilities. The 120 tonnes uranium as UF6 is equivalent to two full fuel loads for a typical 1000 MWe reactor, and is (in 2011) worth some US$ 250 million.

In December 2010 the IAEA board resolved to establish a similar guaranteed reserve of low-enriched uranium, the IAEA LEU bank, with the support of $50 million from the US-based Nuclear Threat Initiative (NTI) organization and US billionaire Warren Buffett, plus a matching $107 million from the US government ($50 million), the EU ($32 million), UAE ($10 million), Kuwait ($10 million) and Norway ($5 million). The IAEA is drawing up a framework that defines the "fuel bank's" structure, access and location. It will comprise a physical stock of UF6 at enrichment levels ranging up to 4.95% U-235 and owned by the IAEA, which shall "be responsible for storing and protecting" it. A comprehensive Host State Agreement will need to provide for the IAEA facility to be extraterritorial. Kazakhstan has offered to host it, and the IAEA has examined two proffered sites. See IAEA Factsheet.

In 2005 the US government announced plans for the establishment of a

mechanism to ensure fuel supply for use in commercial reactors in

foreign countries where there has been supply disruption. The fuel would

come from downblending 17.4 tonnes of high-enriched uranium (HEU). In

August 2011 US Department of Energy announced an expanded scope for the

program so it would also serve US utility needs, and now be called the American Assured Fuel Supply (AFS).

At that point most of the downblending of the HEU had been completed,

and the scheme was ready to operate. The AFS will comprise about 230

tonnes of low-enriched uranium (with another 60t from downblending being

sold on the market to pay for the work). The AFS program is

administered by the US National Nuclear Safety Administration, foreign

access must be through a US entity, and the fuel will be sold at current

market prices. The 230 t amount is equivalent to about six reloads for a

1000 MWe reactor.

Thorium as a nuclear fuel

Today uranium is the only fuel supplied for nuclear reactors.

However, thorium can also be utilised as a fuel for CANDU reactors or in

reactors specially designed for this purpose. Neutron efficient

reactors, such as CANDU, are capable of operating on a thorium fuel

cycle, once they are started using a fissile material such as U-235 or

Pu-239. Then the thorium (Th-232) atom captures a neutron in the reactor

to become fissile uranium (U-233), which continues the reaction. Some

advanced reactor designs are likely to be able to make use of thorium on

a substantial scale.

The thorium fuel cycle has some attractive features, though it is not

yet in commercial use. Thorium is reported to be about three times as

abundant in the earth's crust as uranium. The 2009 IAEA-NEA "Red Book"

lists 3.6 million tonnes of known and estimated resources as reported,

but points out that this excludes data from much of the world, and

estimates about 6 million tonnes overall. See also companion paper on Thorium.

Main references

OECD NEA & IAEA, 2010, Uranium 2009: Resources, Production and Demand

WNA 2009 Market Report

UN Institute for Disarmament Research, Yury Yudin (ed) 2011, Multilateralization of the Nuclear Fuel Cycle - The First Practical Steps.

OECD NEA & IAEA, 2010, Uranium 2009: Resources, Production and Demand

WNA 2009 Market Report

UN Institute for Disarmament Research, Yury Yudin (ed) 2011, Multilateralization of the Nuclear Fuel Cycle - The First Practical Steps.

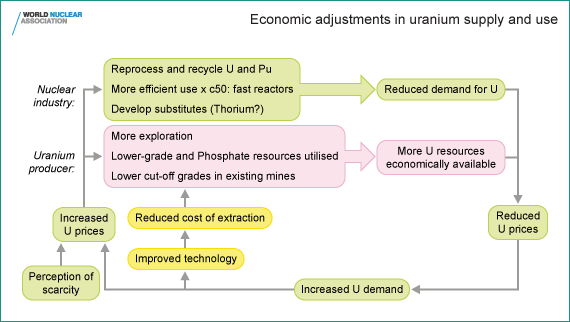

Substantially derived from 2003 WNA Symposium paper by Colin MacDonald, Uranium: Sustainable Resource or Limit to Growth?

- supplemented by his 2005 WNA Symposium paper and including a model

"Economic adjustments in the supply of a 'non-renewable' resource" from

Ian Hore-Lacy.

The Sustainability of Mineral Resources

with reference to uranium

with reference to uranium

It is commonly asserted that because "the resources of the earth are

finite", therefore we must face some day of reckoning, and will need to

plan for "negative growth". All this, it is pointed out, is because

these resources are being consumed at an increasing rate to support our

western lifestyle and to cater for the increasing demands of developing

nations. The assertion that we are likely to run out of resources is a

re-run of the "Limits to Growth" argument (Club of Rome 1972 popularised

by Meadows et al in Limits of Growth at that time. (A useful counter to it is W Berckerman, In Defence of Economic Growth,

also Singer, M, Passage to a Human World, Hudson Inst. 1987). In the

decade following its publication world bauxite reserves increased 35%,

copper 25%, nickel 25%, uranium and coal doubled, gas increased 70% and

even oil increased 6%.) fashionable in the early 1970s, which was

substantially disowned by its originators, the Club of Rome, and shown

up as nonsense with the passing of time. It also echoes similar concerns

raised by economists in the 1930s, and by Malthus at the end of the

18th Century.

In recent years there has been persistent misunderstanding and

misrepresentation of the abundance of mineral resources, with the

assertion that the world is in danger of actually running out of many

mineral resources. While congenial to common sense if the scale of the

Earth's crust is ignored, it lacks empirical support in the trend of

practically all mineral commodity prices and published resource figures

over the long term. In recent years some have promoted the view that

limited supplies of natural uranium are the Achilles heel of nuclear

power as the sector contemplates a larger contribution to future clean

energy, notwithstanding the small amount of it required to provide very

large amounts of energy.

Uranium supply news is usually framed within a short-term

perspective. It concerns who is producing with what resources, who might

produce or sell, and how does this balance with demand? However,

long-term supply analysis enters the realm of resource economics. This

discipline has as a central concern the understanding of not just

supply/demand/price dynamics for known resources, but also the

mechanisms for replacing resources with new ones presently unknown. Such

a focus on sustainability of supply is unique to the long view.

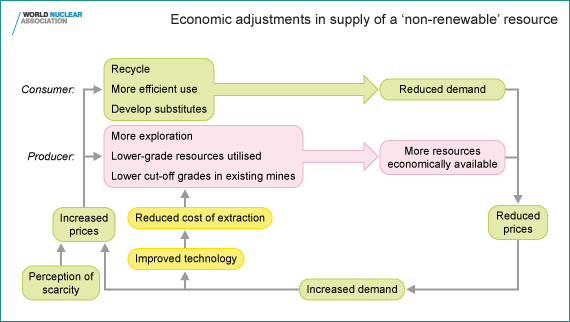

Normally-functioning metals markets and technology change provide the

drivers to ensure that supply at costs affordable to consumers is

continuously replenished, both through the discovery of new resources

and the re-definition (in economic terms) of known ones.

Of course the resources of the earth are indeed finite, but three

observations need to be made: first, the limits of the supply of

resources are so far away that the truism has no practical meaning.

Second, many of the resources concerned are either renewable or

recyclable (energy minerals and zinc are the main exceptions, though the

recycling potential of many materials is limited in practice by the

energy and other costs involved). Third, available reserves of

'non-renewable' resources are constantly being renewed, mostly faster

than they are used.

There are three principal areas where resource predictions have faltered:

- predictions have not accounted for gains in geological knowledge and understanding of mineral deposits;

- they have not accounted for technologies utilised to discover, process and use them;

- economic principles have not been taken into account, which means that resources are thought of only in present terms, not in terms of what will be economic through time, nor with concepts of substitution in mind.

What then does sustainability in relation to mineral resources mean?

The answer lies in the interaction of these three things which enable

usable resources (Some licence is taken in the use of this word in the

following, strictly it is reserves of minerals which are created)

effectively to be created. They are brought together in the diagram

below.

Numerous economists have studied resource trends to determine which measures should best reflect resource scarcity (Tilton, J. On Borrowed Time? Assessing the threat of mineral depletion,

Resources for the Future, Washington DC 2002). Their consensus view is

that costs and prices, properly adjusted for inflation, provide a better

early warning system for long-run resource scarcity than do physical

measures such as resource quantities.